76 CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

The pipe should be able to divert both the incoming flow and

the water volume in the basin, thus emptying it. This is based

on the following equations:

1.5Qdesign = CA hbasin + hflush

or, Qdesign = CA hflush

where:

Qdesign is the design flow. Qdesign is multiplied by 1.5 in the first

equation to ensure that there is a draw down in the water

level inside the basin during flushing (i.e., both the incoming

flow and the flow in the basin can be drained).

C is the orifice coefficient = 2.76 (applies only where the

total pipe length is less than 6 m).

hbasin is the depth of water in the basin during the design flow

prior to flushing.

hflush is the flushing head when basin is empty. This is the

difference in level between the floor of the basin and the

flush pipe outlet as can be seen in Figure 5.6

A is the area of the pipe section.

The second equation ensures that the design flow can be

discharged through the system when the basin is empty. It is

important to check this condition especially if the hflush is low.

d = ( 6Qdesign / ΠC hbasin + hflush )

or,d = (4Qdesign / Π hflush )

In terms of the pipe diameter, the above two equations can be

rewritten as follows:

Note that these equations assume that there is free pipe flow

at the outlet and the pipe diameter is constant (vertical and

horizontal pipes of the system have the same diameter).

All of the above three equations should be used to size the

diameter of the flush pipe. The pipe should be sized using

the equation that results in the largest diameter. If the total

pipe length is more than 6 m, the flow should be calculated

using the guidelines given in Chapter 4.

5.3.8 OTHER CONSIDERATIONS

Spillway requirement

If excess flows can not be spilled from the upstream headrace

portion such as due to lack of a suitable area (or if a pipe is

used), a spillway should also be incorporated at the settling

basin. The spillway should be sized to spill the entire flow

expected during the high flow season. This is because the

plant may need to be shut during high flows for repair work.

The spillway should be located upstream of the basin to avoid

excess flow (and sediment) through the basin. Note that the

design of spillways was covered in Chapter 4.

However, in the case where there is a vertical flush pipe sized to

divert the expected high flows, a separate spillway is not necessary.

Cover

Sometimes there can also be site specific considerations that

need to be addressed during the design of the settling basin.

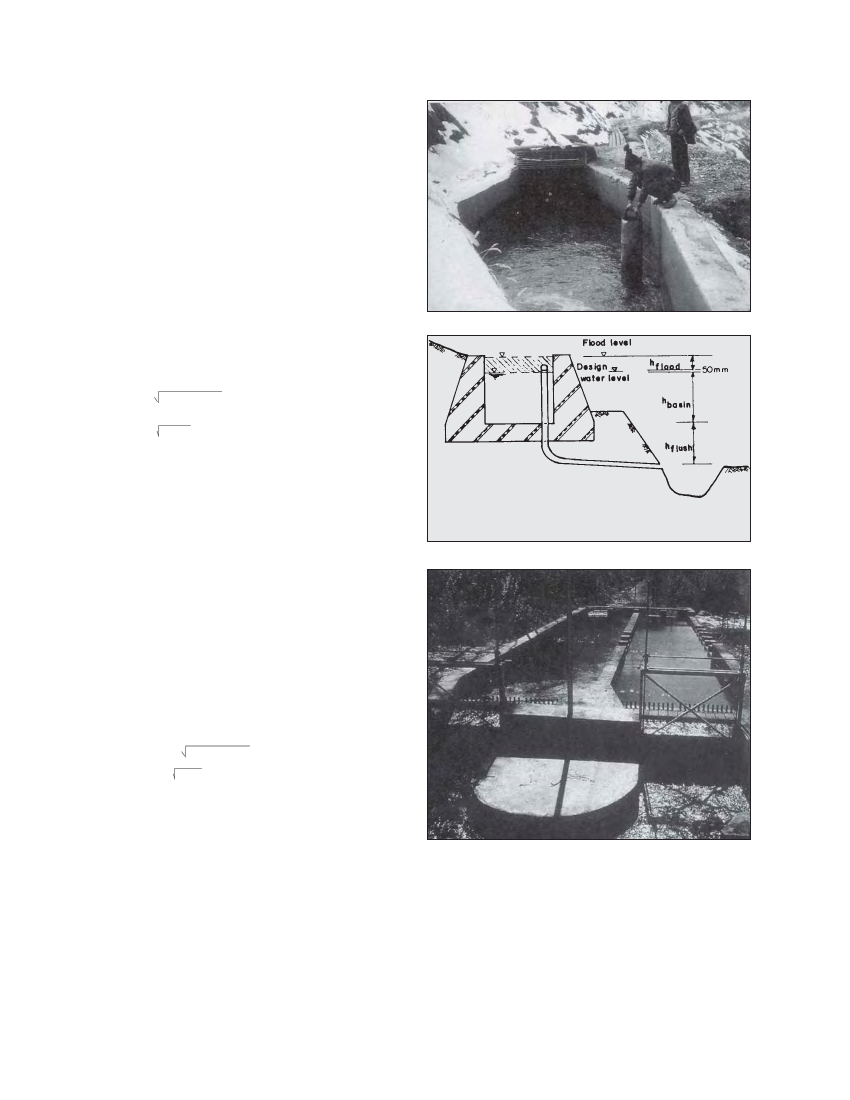

Photo 5.5 Settling basin at Jharkot

Figure 5.6 Vertical flush pipe section in a settling basin

Photo 5.6 Salleri Chialsa settling basin

For example, the Ghandruk settling basin is located in a forest

area and large tree leaves were constantly blocking the

trashrack. This problem was overcome by placing wire mesh

over the basin as can be seen in Photograph 5.7.

Sluice gate

Another conventional method of flushing includes the use of

sluicing gates. This is more common in mini- and large

hydropower schemes. In this system, gates are lifted either

manually or mechanically, to drain the basin. The Salleri